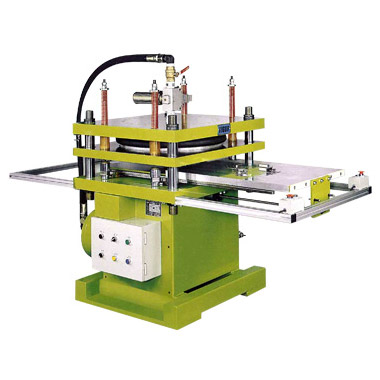

FBCB Die Cutting Presses

VACP-20

FBCB Die Cutting Presses is for flexible printed circuit board punching & shaping.

Features

- With high rigidity structure design. It's able to punch single or multi pieces at the same time. Besides, the finished product looks fine and the cutting edge without burr problem.

- The structure is simple. And it's easy to repair, maintain and set the punch die.

- The simple pneumatic design. It could reduce the noise & vibration while machine running. Besides, it's convenient to be set on 1st floor, 2nd floor or any place.

- With high safe operation design. There is no any operating fear, and it is easy to handle by made and female operator.

Specification

| Item | Unit | VACP-20 |

|---|---|---|

| Capacity | kgs | Max: 20000 |

| Table Area | mm | 610 x 815 |

| Applicable Area of Knife Edge Die(L x W) | mm | 450 x 560 |

| Daylight Opening | mm | 50 |

| Stroke | mm | 30 |

| Operating Speed | sec/cycle | 5 ~ 7 |

| Air Pressure | kg/cm² | 6 |

| Air Consmption | litre/cycle | 40 |

| SIze of Appearance (L x W x H) | mm | 1390 x 900 x 1500 |

| Voltage | V | 單相 110V/220 |

| Weight | kgs | 1600 |

Application

- For flexible printed circuit board punching & shaping.

- Files Download